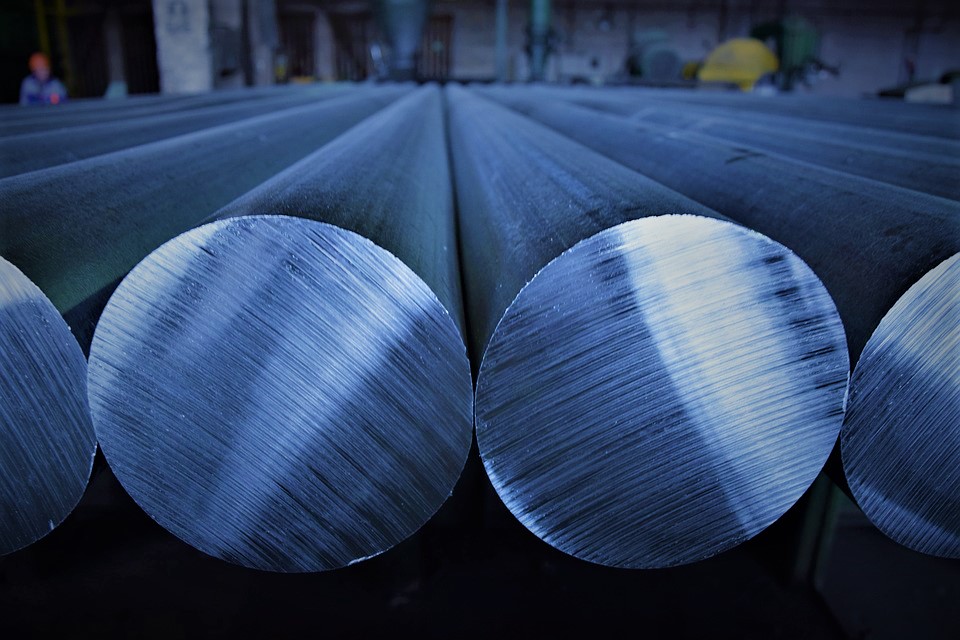

The origins of Sealium®

Created and registered by Alcan Marine, this aluminum alloy, called Sealium®, optimizes the overall productivity of shipbuilders and the performance of ships in general, as it makes ships more robust, safer and more user-friendly.

For vessels of less than 50 m length, they benefit from improved sampling, which results in:

- structural weight savings on patrol boats

- increased resistance on service vessels

- additional interior space in luxury yachts.

Chemical composition of Sealium®

| % | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Zr | other (max.) |

| min. | 0,7 | 4,0 | each: 0,05 | |||||||

| Max. | 0,25 | 0,25 | 0,20 | 1.0 | 5.2 | 0,25 | 0,40 | 0,15 | 0,20 | total 0,15 |

| Reste: Al. (The limits are in maximum percentage unless otherwise indicated) | ||||||||||

Différences between Sealium® and 5083 standard alloy

Benefits of Sealium®

- welded strength limit 15% higher than standard 5083 alloy

- increase of the safety margin of the same samples

- significant weight savings (20% than standard 5083 alloy) thanks to optimized samples

- improved corrosion resistance and increased resistance to fatigue

- same properties of use as alloy 5083

- formability: same cutting, flexing and shaping

- welding: no change in welding procedure, consumables or heat-induced deformation

- greater recycling value for the Sealium® welded assembly.

Disadvantage of Sealium®

- Sealium® is less malleable than AG4.

Sealium® is 25% more expensive than AG4.

Recent Comments